Paper Strip Nails: An Innovative Practical Tool in the Woodworking Field

In fields such as woodworking, furniture assembly, and architectural decoration, nails, as basic connecting components, have always played a crucial role. With the continuous improvement of industry requirements for efficiency, environmental protection, and cost control, traditional metal nails have gradually revealed some limitations. Against this backdrop, paper strip nails, with their unique design and excellent performance, have become a new type of woodworking nail that has attracted much attention in recent years, providing a better solution for the connection needs of various industries.

I. Understanding Paper Strip Nails: Definition and Core Structure

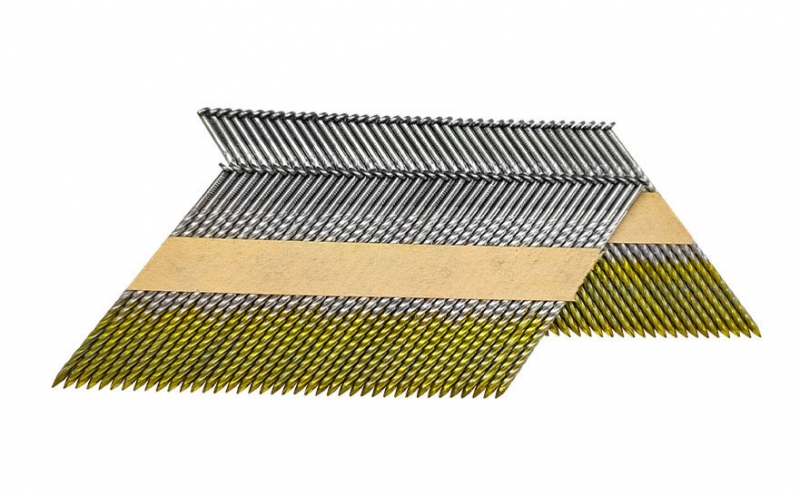

As the name suggests, paper strip nails are long strip-shaped nail sets formed by bonding several individual nails into a regular arrangement with paper. Essentially, they are "integrated nails" designed to adapt to automated nailing equipment and improve construction efficiency. Their core structure consists of two parts, which work together to ensure the stability of the nails while taking into account the convenience of use.

1. Nail Set: The Core Bearing the Connection Function

The nail set is the "framework" of paper strip nails, composed of multiple nails of uniform specifications arranged evenly at fixed intervals. To adapt to the angle requirements of different nailing guns, the nails are not arranged vertically but at a certain inclined angle (commonly 17°, 21°, 28°, 34°, etc.), ensuring smooth nail feeding after being loaded into the equipment. The material, size, and shape of the nails can be flexibly adjusted according to different application scenarios. For example, corrosion-resistant stainless steel nails are used for outdoor scenarios, and thick-threaded nails with large wire diameters are adopted for heavy wood, ensuring connection strength from the source.

2. Single-sided Adhesive Paper Strip: The Key to Realizing "Integration"

The single-sided adhesive paper strip is the core component that "connects" individual nails in a series. It is usually made of high-strength, degradable paper material, with hot-melt adhesive evenly applied on its surface. During use, the hot-melt adhesive adheres to the front and back of the nail set respectively, firmly fixing the scattered nails into a whole. This not only prevents the nails from scattering during transportation and storage but also enables quick peeling of the paper strip through the "paper tearing mechanism" of the equipment during nailing, realizing continuous nail feeding and completely solving the problem of "frequent nail loading and low efficiency" of traditional loose nails.

II. Specification Parameters of Paper Strip Nails: A "Customized Solution" for Different Scenarios

One of the advantages of paper strip nails lies in their rich range of specifications. Whether in terms of material, size, or surface treatment, they can be flexibly adjusted according to specific needs to ensure optimal performance in different scenarios. The following is a detailed analysis of their core specification parameters:

1. Nail Angle: Adapting to Different Nailing Equipment

Common angles include 17°, 21°, 28°, and 34°, with different angles corresponding to different types of pneumatic nailing guns. For example, 17° angle paper strip nails are mostly used for light woodworking splicing (such as fixing furniture back panels), while 34° angle ones are suitable for heavy-duty plate connection (such as installing building wood keels). When purchasing, it is necessary to strictly match the equipment angle to avoid problems such as nail jamming and poor nail feeding.

2. Material: Balancing Strength and Environmental Adaptability

Q235 Steel: The most cost-effective basic material, with certain strength and toughness, suitable for ordinary woodworking scenarios in dry indoor environments (such as panel furniture assembly);

45# Steel: A high-strength material with higher hardness after heat treatment, suitable for connection scenarios under large pressure (such as fixing the load-bearing frame of wooden boxes);

SS304/SS316 Stainless Steel: Corrosion-resistant materials that can resist the erosion of humid, acid, and alkali environments, often used in outdoor decoration (such as fixing the exterior wall panels of wooden houses), bathroom furniture, or marine equipment packaging;

Copper: Possessing both aesthetic appearance and corrosion resistance, it is mostly used in high-end decoration scenarios (such as splicing retro furniture, fixing copper art decorations), but the cost is relatively high.

3. Size: Matching Materials of Different Thicknesses

Nail Length: 50mm - 160mm. Short nails (50 - 80mm) are suitable for thin plates (such as furniture panels, packaging cartons), while long nails (100 - 160mm) are suitable for thick wood or multi-layer plate splicing (such as wooden bed frames, building wooden beams);

Wire Diameter: 2.5mm - 4.6mm. The thicker the wire diameter, the higher the tensile strength of the nail. For example, a 2.5mm wire diameter is suitable for fixing lightweight materials, and a 4.6mm wire diameter is used for heavy-duty load-bearing structures.

4. Nail Shank Type and Surface Treatment: Enhancing Connection Stability and Durability

Nail Shank Type: Smooth shank nails have low installation resistance and are suitable for soft wood; annular and threaded shank nails have raised patterns on the surface, which can enhance the bite force with wood, prevent loosening, and are more suitable for hard wood or vibration environments (such as mechanical equipment packaging);

Surface Treatment: Polishing treatment improves the surface smoothness and reduces nail feeding resistance; electro-galvanizing, hot-dip galvanizing, and mechanical galvanizing can enhance rust resistance (hot-dip galvanizing has better rust resistance than electro-galvanizing); heat treatment can improve the hardness of nails and extend their service life.

III. Characteristic Advantages of Paper Strip Nails: Why Can They Replace Traditional Metal Nails?

Compared with traditional loose metal nails or all-metal strip nails, paper strip nails show significant advantages in three aspects: environmental protection, cost, and performance, making them an important choice for industry upgrading.

1. Environmental Protection: Conforming to the Trend of Green Development

The paper strips of paper strip nails are made of renewable paper materials. The waste generated during the production process is much less than that of all-metal strip nails (no need to handle a large amount of metal processing waste). At the same time, the remaining paper strips after use can be recycled and reused, and even if discarded, they can be naturally degraded, avoiding environmental pollution caused by metal waste. For enterprises that focus on "green production", choosing paper strip nails can not only reduce environmental pressure but also enhance the brand's environmental image.

2. Cost Advantage: Reducing the Comprehensive Expenses of Enterprises

In terms of material cost, the price of paper materials is much lower than that of metal. Compared with all-metal strip nails, the material cost of paper strip nails can be reduced by 15% - 30%; in terms of use cost, the continuous nail feeding design greatly reduces the manual nail loading time. Taking a furniture factory as an example, the use of paper strip nails can increase the nailing efficiency by more than 40%, indirectly reducing labor costs; in addition, the transportation and storage costs of paper strip nails are also lower - the same number of paper strip nails have a smaller volume and lighter weight, which can reduce storage space and logistics costs.

3. Performance Advantage: Protecting Materials and Improving Connection Stability

The "distributed force" design of paper strip nails is their core performance highlight: when nailing with traditional loose nails, the concentrated local force is likely to cause wood cracking and plate deformation; however, paper strip nails can disperse external forces to multiple connection points through the buffer effect of evenly arranged nails and paper strips, effectively reducing the risk of material damage. At the same time, the hot-melt adhesive will melt slightly during the nailing process, forming a secondary bond with the wood surface, further improving the connection firmness. They are especially suitable for fixing soft wood (such as pine, fir) or brittle materials (such as bamboo).

IV. Application Scope of Paper Strip Nails: "Full-scenario Coverage" from Woodworking to Construction

With their diverse specifications and excellent performance, paper strip nails have covered various industries in application scenarios and become a "versatile hand" in the connection field.

1. Woodworking and Furniture Manufacturing Industry

It is the core application field of paper strip nails, including:

Solid wood furniture: Frame splicing, back panel fixing, and drawer assembly (17° - 21° angle, Q235 steel or stainless steel nails are commonly used);

Panel furniture: Edge banding reinforcement and auxiliary fixing of connectors (short nails, smooth shank or annular shank nails are suitable);

Bamboo products: Splicing of bamboo chairs, bamboo cabinets, and other bamboo products (to avoid bamboo cracking, nails with good toughness should be selected).

2. Packaging and Transportation Industry

Mainly used for wooden box packaging, such as:

Large equipment packaging: Fixing the wooden box frame of heavy mechanical equipment (45# steel, long nails with large wire diameters should be selected to ensure load-bearing capacity);

Precision instrument packaging: Protecting instruments from impact through distributed force (stainless steel nails are suitable to prevent rust pollution to instruments during transportation);

Logistics cartons: Sealing and reinforcing high-strength cartons (short nails and lightweight materials are used to reduce packaging weight).

3. Construction and Decoration Industry

Covering multiple indoor and outdoor construction scenarios:

Interior decoration: Fixing of ceiling keels and installation of wall decoration panels (such as gypsum boards, wooden boards) (21° - 28° angle nails are commonly used, balancing efficiency and strength);

Outdoor construction: Wooden house construction and outdoor fence installation (SS304/SS316 stainless steel nails are required to resist wind and rain);

Earth wall sand turning: Auxiliary fixing in the reinforcement of traditional earth walls and sand turning construction (nails with corrosion resistance and strong adaptability are suitable).

V. Purchase and Use Suggestions for Paper Strip Nails

To give full play to the advantages of paper strip nails, it is necessary to master the correct purchase methods and use skills to avoid affecting the effect due to improper selection or operation errors.

1. Purchase Points: Accurately Matching Needs

Clarify the Scenario: First, determine the use environment (dry/humid, indoor/outdoor), connection material (wood/bamboo/plastic), and force requirement (load-bearing/non-load-bearing), then select the corresponding material, size, and angle. For example, stainless steel nails must be selected for outdoor scenarios, and 45# steel long nails are required for heavy load-bearing;

Check Quality: High-quality paper strip nails should meet the standards of "no rust or burrs on the nails, firm adhesion of the paper strip without loosening or falling off, and uniform angle without deviation". Sampling tests can be conducted: load the paper strip nails into the nailing gun and observe whether there are problems such as nail bending, breaking, or excessive residual paper strip after test nailing;

Choose Regular Manufacturers: Products from regular manufacturers with formal production qualifications and good reputation have undergone strict quality inspections during the production process, so their quality is more guaranteed. At the same time, they can provide perfect after-sales services, such as return and exchange for product quality problems and technical support during use. Avoid purchasing "three-no products" - inferior paper strip nails may have problems such as insufficient nail strength and easy breakage of the paper strip, which will increase construction risks instead.

2. Use Skills: Improving Efficiency and Effect

Matching Nailing Equipment: Ensure that the angle of the nailing gun is consistent with that of the paper strip nails (for example, a 17° angle nail requires a 17° nailing gun). At the same time, adjust the pressure of the nailing gun: reduce the pressure for soft materials to avoid material damage; increase the pressure for hard materials to ensure that the nails are fully driven in;

Storage Precautions: Paper strip nails should be stored in a dry and ventilated environment to prevent the paper strip from getting damp and moldy or the nails from rusting. Especially for stainless steel nails and copper nails, although they are corrosion-resistant, long-term exposure to a humid environment may still affect their performance;

Safe Operation: When using a nailing gun, wear protective glasses and gloves to avoid injury from nail rebound or debris; keep away from children and irrelevant personnel during nailing to ensure a safe construction environment.

Conclusion

The upgrade from traditional loose nails to paper strip nails is not only an innovation in connecting tools but also a response to the industry's demand for "high efficiency, environmental protection, and low cost". Whether furniture factories pursue production efficiency, packaging enterprises control costs, or the construction industry focuses on construction quality, paper strip nails can provide suitable solutions with their diverse specifications, excellent performance, and significant advantages. With the in-depth development of the concept of green production and the popularization of automated equipment, paper strip nails will definitely play a role in more fields and become the "mainstream choice" in the woodworking connection field.

Send Email

Send Email