Description of Product

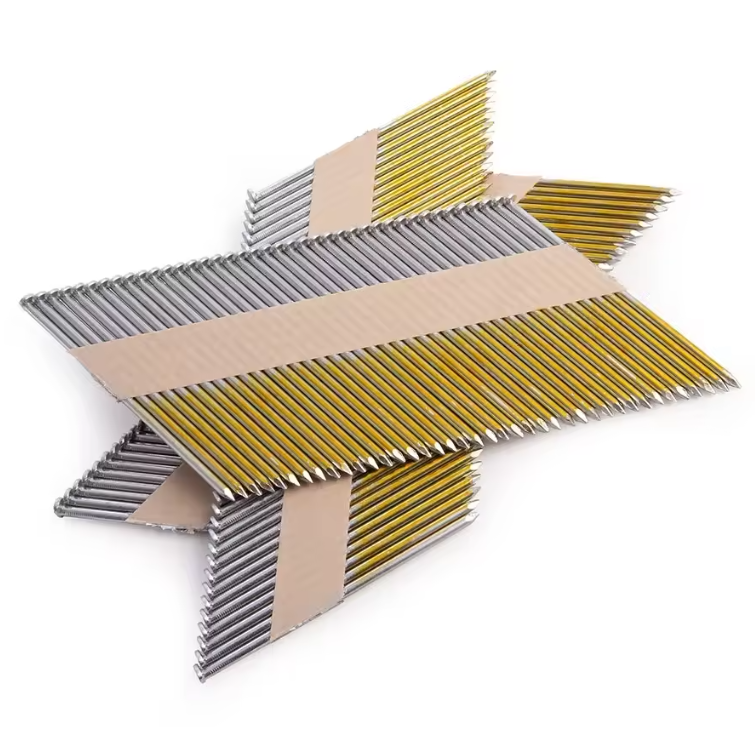

Paper tape collated nails are specialized fasteners that are neatly arranged and bonded to paper strips, designed exclusively for use with pneumatic nail guns. As a staple in professional construction and woodworking fields, they stand out for their efficient nailing performance and reliable fixing capabilities. Manufactured via precision processes including wire drawing, quenching, and automatic paper tape collation, these nails come in common collation angles such as 33° and 34°, which are compatible with most standard pneumatic nail guns on the market. Available in ring, screw, and smooth shank designs, they are made from materials like high-carbon steel, 304 stainless steel, and 316 stainless steel to meet diverse requirements of different construction scenarios. Suitable for large-scale and high-intensity operations, they are widely used in decking, framing, sheathing, furniture assembly, and pallet production, significantly boosting construction efficiency while ensuring stable fixing results.

Smooth Nailing & Reduced Jamming: The nails are precisely positioned and bonded on the paper tape through automated collation technology, guaranteeing uniform spacing. The 33° or 34° collation angle is optimized to match the feeding mechanism of pneumatic nail guns, enabling smooth nail feeding during continuous operation. This design minimizes jamming issues that often occur with manual nailing, greatly improving construction continuity and work efficiency, which is ideal for large-volume construction projects.

Strong Grip & Anti-Loosening: The ring or screw shank variants enhance friction between the nail and the base material. When driven into wood or other substrates, they form a tight fit that effectively prevents loosening and detachment due to external forces. The chisel or diamond points are sharp enough to pierce materials easily, reducing splitting of woodwork, while the high-carbon steel material ensures the nails have excellent bending resistance and impact resistance, avoiding deformation during nailing.

Eco-Friendly Collation & Cost-Effective: The paper tape used for collation is made of recyclable plant fiber materials, which is more environmentally friendly compared to plastic or metal collation strips as it produces less pollution during disposal. Additionally, the lightweight paper tape reduces the overall weight of the nail strips, facilitating transportation and storage. The simple collation structure also lowers production costs, offering a cost-effective solution for bulk procurement by construction teams and woodworking factories.

Wide Compatibility & Customizable Specifications: It is compatible with most mainstream pneumatic nail gun models on the market. The product covers a wide range of specifications, with diameters from 2.8mm to 3.4mm and lengths from 50mm to 100mm (equivalent to 2 inches to 4 inches). It also supports customized collation angles, shank types, and surface treatments according to special engineering needs, fully adapting to different construction scenarios such as floor laying, furniture assembly, and crate production.

| Specification Parameters | Detailed Description |

|---|

| Material Type | Standard steel, 304 stainless steel, 316 stainless steel, high-carbon steel, etc. |

| Diameter Range | 2.8mm - 3.4mm (0.11 inches - 0.13 inches), suitable for fixing materials of different thicknesses. |

| Length Range | 50mm - 100mm (2 inches - 4 inches). Common specifications include 50mm, 75mm, 90mm, etc., for various construction needs. |

| Collation Details | Collation angle: 20°, 33°, 34°, etc. (33° and 34° are mainstream for pneumatic nail guns); strip capacity: 22 - 55 nails per strip, with some models holding up to 36 nails. |

| Surface Treatment | Bright finish, electro-galvanized, hot-dip galvanized, black oxidated. Electroplated and hot-dip galvanized variants have strong corrosion resistance for outdoor use. |

| Nail Structure | Head type: Full round offset head, flat head; Point type: Chisel point, diamond point; Shank type: Ring, screw, smooth. |

| Packaging Specifications | 3000 - 5000 nails per package; customized packaging is available for bulk orders to meet the needs of different procurement scales. |

Woodworking & Furniture Manufacturing: Widely used in furniture frame assembly, solid wood door and window production, and wooden cabinet splicing. The ring-shank paper tape collated nails ensure the stability of furniture structures, and their smooth nailing feature prevents damage to the appearance of wooden components, suitable for both mass production in factories and custom-made furniture workshops.

Construction & Decoration: Ideal for floor laying, wall sheathing, and roof framing in construction projects. The corrosion-resistant stainless steel or hot-dip galvanized models can withstand humid or outdoor environments, making them suitable for outdoor decking and fence installation. They are also used for fixing decorative panels and lightweight partitions during interior decoration.

Packaging & Crate Industry: Used in the production of wooden pallets and shipping crates. The efficient continuous nailing performance matches the assembly line operation needs of the packaging industry, improving the speed of crate production while ensuring the crates are strong enough to protect goods during transportation.

Prefabricated Housing & Modular Construction: In the assembly of prefabricated houses and modular components, the paper tape collated nails can quickly fix light steel frames and wooden cladding materials. Their compatibility with pneumatic tools adapts to the efficient assembly requirements of modular construction, ensuring the stability and precision of component connections.