Description of Product

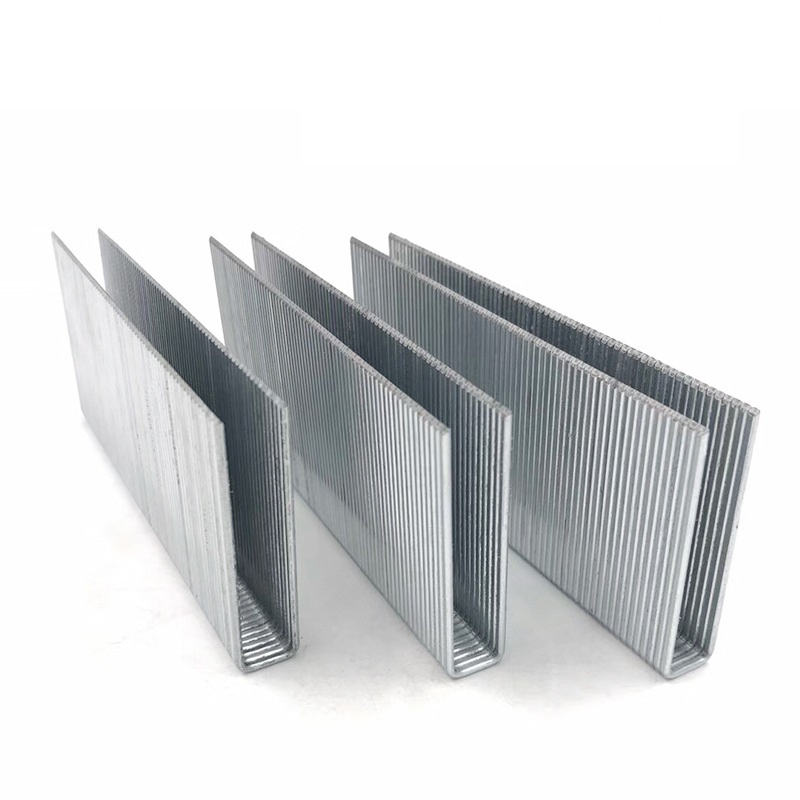

U-Type Staples (also known as U-staples or code staples) are high-efficiency fasteners with a "U" shaped structure. Manufactured from high-quality steel through precision stamping, quenching, and surface treatment processes, they are exclusively designed for use with pneumatic staple guns, offering superior holding power, easy operation, and high efficiency. Featuring uniform leg thickness, sharp tips, and a shoulder curve that fits the base material, these staples can quickly penetrate various materials such as wood, leather, and fabric while providing a secure clamping effect. Available in materials including high-carbon steel, galvanized steel, and 304 stainless steel, with specifications covering light-duty, medium-duty, and heavy-duty series, they are widely used in furniture manufacturing, construction and decoration, packaging reinforcement, leather processing, gardening fencing, and other fields. They are indispensable high-efficiency fixing consumables for industrial production and handcrafting.

Scientific Structure & Secure Fixing: The classic U-shaped design forms a three-point stress clamping structure with symmetrically distributed, precisely spaced legs. After being driven into the base material, it tightly interlocks with the material, providing strong clamping force to effectively prevent loosening and detachment. Compared to ordinary straight nails, it is more suitable for scenarios requiring stable clamping such as thin-sheet material fixing and frame splicing.

Sharp & Tough with Strong Penetration: Made of high-carbon steel and quenched, the staple body offers high hardness and strong bending resistance, avoiding deformation and breakage. The finely ground sharp tips can easily penetrate various substrates including wood, plywood, leather, and plastic, while reducing the risk of material cracking, adapting to the fixing needs of materials of different thicknesses.

Wide Compatibility & Efficient Operation: Compatible with mainstream pneumatic staple gun models on the market, supporting continuous stapling operations without frequent staple replacement, significantly improving construction efficiency. Compared to manual nailing, it reduces labor intensity, especially suitable for mass production and large-area construction scenarios such as furniture assembly lines and bulk packaging in packaging factories.

Multiple Material Options & Excellent Weather Resistance: Available in various materials including high-carbon steel (natural finish), electro-galvanized high-carbon steel, hot-dip galvanized high-carbon steel, and 304 stainless steel. Among them, galvanized and stainless steel models offer excellent rust and corrosion resistance, suitable for use in humid environments and outdoor scenarios, extending service life. The smooth, burr-free surface prevents scratching the surface of the fastened material.

| Specification Parameters | Detailed Description |

|---|

| Material Type | High-carbon steel, electro-galvanized high-carbon steel, hot-dip galvanized high-carbon steel, 304 stainless steel |

| Model Series | Light-duty (1000 series), Medium-duty (4000 series), Heavy-duty (7000 series) |

| Leg Diameter | 1.0mm - 2.0mm; 1.0mm - 1.2mm for light-duty models, 1.6mm - 2.0mm for heavy-duty models |

| Leg Length | 6mm - 50mm; Common specifications: 8mm, 10mm, 12mm, 15mm, 20mm, 30mm, 40mm |

| Crown Width | 8mm - 16mm, corresponding to different models: 1006 (8mm), 410J (10mm), 715 (15mm), etc. |

| Surface Treatment | Natural finish (bright finish), electro-galvanized, hot-dip galvanized, black oxide treatment |

| Packaging Specifications | 1000 pieces/box, 5000 pieces/box, 10000 pieces/box; Custom packaging available for bulk orders with bilingual (Chinese-English) specification labels |

Furniture Manufacturing & Woodworking: Used for sofa frame fixing, seat fabric upholstery, wooden cabinet back panel splicing, decorative molding installation, etc. The U-shaped structure can firmly clamp fabric and wood to avoid loosening, while the sharp tips do not damage the wood surface, adapting to the refined needs of furniture production.

Construction & Decoration Projects: Applicable to gypsum board fixing, ceiling keel splicing, skirting board installation, door and window seal strip 装订,etc. Continuous stapling efficiency accelerates construction progress; galvanized or stainless steel models can be selected for outdoor fencing, log cabin construction, and other scenarios to withstand wind and rain, extending service life.

Packaging & Logistics Industry: Used for carton reinforcement, wooden box sealing, pallet splicing, package bundling, etc., especially suitable for fixing thin sheets and cartons. The strong clamping force of U-type staples prevents package loosening during transportation, improving the safety of goods transportation.

Leather & Fabric Processing: Suitable for leather goods production, sofa fabric upholstery, curtain fixing, carpet installation, etc. The smooth, burr-free staple body does not scratch soft materials such as leather and fabric, while providing secure fixing to avoid detachment, meeting the needs of handcraft workshops and factory mass production.

Gardening & Other Fields: Used for gardening fence construction, plant support fixing, exhibition panel installation, advertising banner fixing, etc. Easy to operate, it can quickly complete fixing, adapting to both temporary construction and long-term use scenarios.