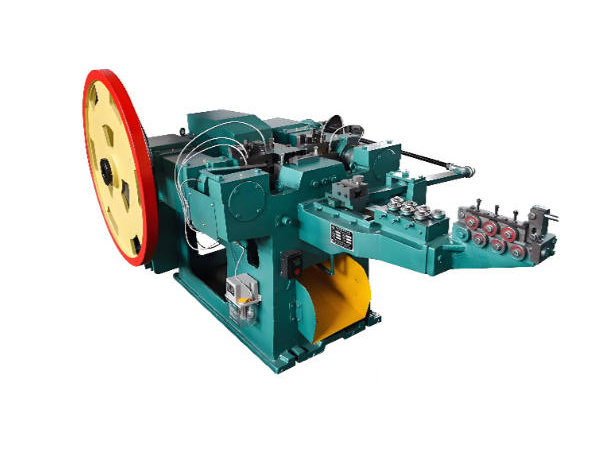

Nail Making Machine Buying Guide: Choose Our Nail Making Machine to Start a New Chapter of Efficient Production

In today's rapidly developing industries such as construction, furniture manufacturing, and hardware processing, nails, as basic connectors, have maintained a steady growth in demand. As the core equipment for nail production, nail making machines directly determine an enterprise's production capacity and profit margin with their performance, efficiency, and stability. If you are struggling to find a high-quality nail making machine, you may wish to gain an in-depth understanding of our nail making machine products, which will inject strong momentum into your production business.

I. Our Nail Making Machine: Outstanding Performance to Meet Diverse Production Needs

(I) Efficient Production to Increase Capacity

Our nail making machine adopts an advanced transmission system and precise mechanical structure, which greatly shortens the production cycle of each nail. Taking ordinary - sized round nails as an example, the hourly output of ordinary nail making machines is about 8,000 - 12,000 pieces, while the hourly output of our nail making machine can stably reach 15,000 - 20,000 pieces, with a capacity increase of more than 25%. Whether it is small - batch customized production or large - scale bulk supply, it can be easily handled, helping enterprises quickly respond to market orders and seize market share.

(II) High - Quality Materials for Durability

The durability of equipment is one of the key factors for enterprises to control production costs. The body of our nail making machine is made of high - strength steel, which has undergone precise processing and strict quality inspection to ensure that the body has excellent compression resistance and deformation resistance, and can withstand long - term and high - intensity production operations. At the same time, the core components of the equipment, such as molds and cutters, are made of high - quality alloy materials, which have excellent wear resistance and toughness. Their service life is extended by more than 30% compared with ordinary components, effectively reducing the frequency of component replacement and maintenance costs.

(III) Intelligent Control for Easy Operation

In order to reduce the labor intensity of operators, improve production efficiency and the stability of product quality, our nail making machine is equipped with an advanced intelligent control system. Operators can easily set production parameters (such as nail length, diameter, output, etc.) through a clear and easy - to - understand touch screen interface, and the system will automatically and accurately control the operation process of the equipment. At the same time, the equipment is also equipped with a complete fault diagnosis function. When an abnormal situation occurs in the equipment, the system will promptly issue an alarm and display the cause of the fault, facilitating maintenance personnel to quickly troubleshoot and solve the problem, and reducing the downtime of the equipment.

(IV) Flexible Adaptation for Multi - Specification Production

The market has diverse demands for nail specifications. Different industries and application scenarios require nails of different lengths, diameters, and shapes. Our nail making machine has excellent flexibility and adaptability. By replacing molds of different specifications and simply adjusting production parameters, it can realize the production of nails of various specifications. Whether it is common round nails, cement nails, or special - specification corrugated nails, shoe nails, etc., it can produce them efficiently and accurately, meeting the diverse needs of customers, helping enterprises expand product categories, and improving market competitiveness.

II. Choose Us to Enjoy Comprehensive High - Quality Services

(I) Professional Customized Solutions

We are well aware that each enterprise has differences in production scale, site conditions, and product needs. Therefore, we will arrange a professional technical team to conduct in - depth communication with customers, fully understand the actual situation and needs of customers, and customize personalized nail making machine procurement solutions and production layout solutions for customers. From the selection of equipment models, the configuration of production lines to the planning of equipment installation locations, we will provide professional suggestions and support to ensure the feasibility and practicality of the plan, and help customers achieve the optimal production configuration.

(II) Full - Process Installation and Commissioning

After customers purchase the equipment, we will send an experienced installation and commissioning team to the customer's production site to carry out equipment installation and commissioning work. The installation team will strictly follow the equipment installation specifications and the customer's site requirements to ensure that the equipment is installed firmly and accurately, and all components are connected smoothly. During the commissioning process, technical personnel will carefully adjust and test various performance parameters of the equipment to ensure that the equipment reaches the best operating state, and conduct trial production to allow customers to see the production effect of the equipment with their own eyes. At the same time, they will also provide on - site training for the customer's operators, explaining in detail the operation methods, precautions, and daily maintenance knowledge of the equipment to ensure that the operators can proficiently master the equipment operation skills.

(III) Complete After - Sales Support

We always put the interests of customers first and provide customers with complete after - sales support services. If there is a quality problem with the equipment under normal use, we will, in accordance with the after - sales service commitment, respond within 2 hours after receiving the customer's repair request, and arrange maintenance personnel to go to the site for repair and treatment within 48 hours (except for remote areas). At the same time, we have also established a sufficient spare parts warehouse to ensure that when parts need to be replaced, they can be supplied quickly, reducing the downtime of the equipment. In addition, we will also conduct regular return visits to customers to understand the use of the equipment, provide technical support and maintenance suggestions, and help customers better maintain the equipment and extend its service life.

III. Customer Testimonials: Choose Our Nail Making Machine to Achieve Production Take - off

Case 1: A Hardware Products Factory

This hardware products factory originally used ordinary nail making machines, which had low production efficiency and unstable product quality. Problems such as nail size deviation and uneven surface often occurred, leading to a high customer complaint rate and a gradual decrease in orders. After learning about our nail making machine products, the person in charge of the factory decided to purchase one for trial use. After use, the factory was pleasantly surprised by the efficiency and stability of the equipment. The hourly output increased by 40% compared with before, and the product qualification rate increased from 85% to more than 99%. Later, the factory purchased 3 more of our nail making machines, expanded the production scale, and achieved a significant increase in product sales and customer satisfaction.

Case 2: A Construction Material Supplier

This construction material supplier mainly provides nails and other hardware building materials for local construction projects. With the continuous expansion of its business, the original nail making equipment could no longer meet the growing order demand. Through the introduction of a friend, the supplier learned about our nail making machine and conducted an on - site inspection of our production base and customer use site. After a comprehensive comparison, it finally chose our nail making machine. After the equipment was put into use, it not only met the order demand, but also obtained more long - term cooperative orders for construction projects due to the stable product quality, and the economic benefits of the enterprise achieved a significant improvement.

Send Email

Send Email