Coil Nails: A Pioneering Fastener for Multi-Domain Applications

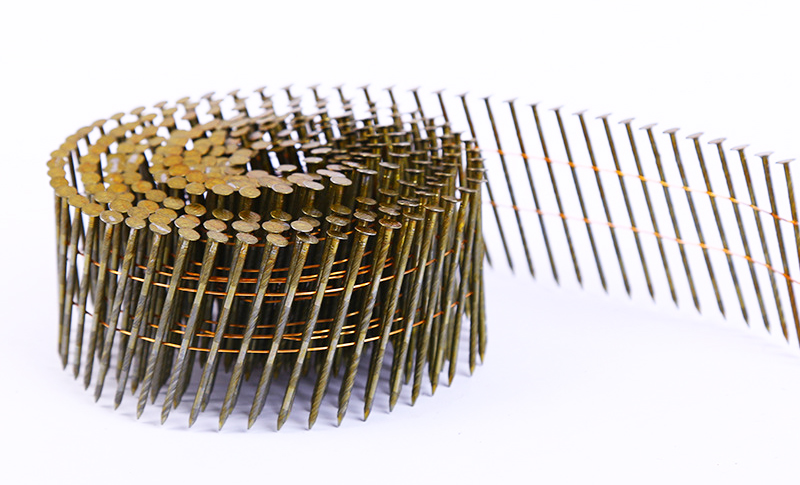

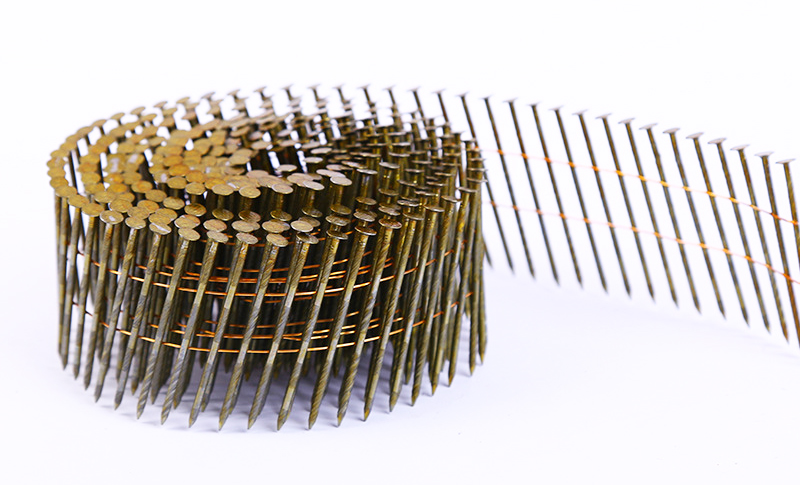

In modern industrial production and engineering construction, the selection of fasteners directly impacts operational efficiency and finished product quality. As a high-efficiency nail product composed of multiple equidistantly arranged nails connected by copper-plated iron wire, coil nails have deeply penetrated core fields such as construction, furniture manufacturing, and packaging, thanks to their compatibility with mechanical nailing operations, strong holding power, and user-friendly design. They have become an indispensable fastening "tool" across various industries.

I. Construction Industry: Fortifying the Core Line of Structural Stability

Construction projects demand high reliability and construction efficiency in fastening, where coil nails demonstrate unique advantages. In door and window installation, coil nails paired with professional coil nail guns can quickly secure door and window frames tightly to the wall base. Compared to traditional manual nailing, this not only significantly shortens construction time but also ensures uniform force distribution at fixed points, effectively preventing loosening, deformation, and other issues during door and window use. In ceiling engineering, coil nails play a crucial role in connecting ceiling keels to the ceiling base. Their evenly spaced design and strong penetration power guarantee the flatness and stability of keel installation, laying a solid foundation for subsequent ceiling decoration. Additionally, in outdoor construction components such as exterior wall panels and roof shingles, specialized coil nails excel: 2 1/2-inch coil siding nails can firmly grip various materials including wood and fiber cement, maintaining stable fastening performance even under harsh conditions like wind and sun exposure; ring-shank coil roofing nails enhance friction with materials through a special ringed design, effectively preventing roof shingle detachment and building the first line of defense against water and wind for building exteriors and roofs.

II. Furniture Manufacturing Industry: The Key to Balancing Stability and Aesthetics in Assembly

The service life and user experience of furniture largely depend on the firmness of component connections, and coil nails perfectly balance stability and aesthetics in furniture manufacturing. In the assembly of cabinets, wardrobes, bed frames, and other cabinetry and frame-type furniture, coil nails can be flexibly selected based on the stress requirements of different components: smooth-shank coil nails are suitable for general panel splicing, ensuring secure connections while minimizing damage to the panels; ring-shank or threaded coil nails, with their special textured designs, significantly improve holding power and are specifically used for high-stress load-bearing parts of furniture, such as the joints between bed legs and frames or the corners of cabinet bodies, ensuring furniture remains stable without loosening or wobbling during long-term use. Meanwhile, mechanical nailing with coil nails ensures precise positioning and consistent depth, avoiding issues like exposed nail heads and panel cracking caused by manual nailing. This results in a cleaner furniture appearance and a 3-5x increase in assembly efficiency, making coil nails a core fastener in large-scale furniture production lines.

III. Packaging Industry: Creating a Safe and Reliable Transportation Guarantee

In wooden packaging and logistics pallet manufacturing, coil nails are critical for ensuring the safety of goods during transportation. As the primary packaging method for heavy goods and precision equipment, wooden packaging boxes require exceptional compression and impact resistance. Coil nails can quickly splice the side panels, bottom panels, and cover panels of packaging boxes into sturdy containers, effectively preventing box collapse during long-distance transportation and protecting internal goods from damage. In logistics pallet assembly, the advantages of coil nails are even more pronounced: as core tools for cargo bearing and handling, pallets must withstand cargo weight and frequent loading/unloading friction. Coil nails firmly secure the stringers, crossbeams, and decking of pallets, ensuring tight component connections, resistance to deformation and collapse, and a significant extension of pallet service life and reuse rate, thereby reducing logistics packaging costs.

IV. Decoration and Renovation Industry: An Aesthetic Assistant for Improving Construction Efficiency

Interior and exterior decoration pursues a balance between efficient construction and aesthetic results, where coil nails play an important supporting role. In indoor decorative wall panel installation, traditional manual nailing is time-consuming and labor-intensive, often leading to uneven panel splicing and exposed nail heads that affect appearance. In contrast, coil nails paired with coil nail guns can quickly fix wall panels to the wall base, with nail heads precisely embedded in the panel surface for subsequent sanding and painting, resulting in a smoother and more attractive wall finish. Additionally, in the fixation of metal decorative parts and wooden decorative moldings, coil nails, with their compact size and strong penetration power, enable rapid fastening without damaging the appearance of decorative components. They are particularly suitable for large-area decoration projects such as hotels and shopping malls, effectively shortening construction cycles and improving overall renovation efficiency.

V. Other Industries: Versatile Fasteners for Cross-Domain Empowerment

Beyond core fields, coil nails demonstrate strong adaptability in various niche scenarios. In the automotive manufacturing industry, coil nails are used for fixing automotive interior components, such as the connection between seat fabrics and cushion bases and the assembly of door trim panels. Their precise fastening effect prevents abnormal noises from interior parts during vehicle operation. In bamboo product manufacturing, coil nails are employed for splicing and fixing bamboo furniture and woven bamboo crafts, preserving the natural texture of bamboo while ensuring product structural stability. Furthermore, in specialized scenarios like adobe wall sanding and temporary shed construction, coil nails meet the fastening needs of temporary or special environments through their user-friendly design and reliable performance.

From the structural construction of high-rise buildings to the precision assembly of daily furniture, from the safe packaging of heavy goods to indoor and outdoor decoration, coil nails have become a cross-industry fastening "backbone" with their core advantages of efficiency, stability, and convenience. As industrial production technology continues to advance, the materials, specifications, and application scenarios of coil nails will continue to expand, providing more solid fastening support for the high-quality development of various industries.

Send Email

Send Email